What is Faucet?

Faucet is also called tap, it is used to control the size of water flow and has the effect of saving water. The replacement of faucets is very fast, from old cast iron technology processing to electroplating knob type, as well as developing stainless steel single temperature single control faucet, stainless steel dual temperature double control faucet, and kitchen faucet, bathroom faucet. Nowadays, more and more consumers buy faucets, and they will comprehensively consider the material, function, shape, and other aspects. The faucet has changed from a practical tool to more ornamental multifunctional daily essential products.

What’re the Faucets Types?

1. Sort by material: faucet can be divided into SUS 304 stainless steel faucet, plastic ABS faucet, brass tap faucet, zinc alloy material faucet, polymer composite (PP Material) faucet, and so on.

Brass: Brass is the most common material made from faucets. It is made of H59/H62 copper of international standard and is cast by gravity with a steel mold with a uniform wall thickness of 2.5-3.0 mm.

Characteristics: no rust, durable, anti-oxidation, the bactericidal effect on water (disadvantage is: lead included, Lead is a metal that is harmful to health. International standards require that copper contain no more than 2.5% lead. The current market general faucet copper materials can basically meet this standard.

Stainless steel: Stainless steel is an internationally recognized health material that can be implanted into the human body, so stainless steel as the main material of kitchen and bathroom supplies have begun to popular in Europe and the United States.

However, because of the high hardness and toughness of stainless steel material, it is difficult to manufacture and process, which seriously affects the mass production of stainless steel faucet, so the price of real 304 stainless steel faucet is higher than that of copper.

Features: healthy, environmentally friendly; all products are made of high quality 304 stainless steel, no rust, no lead, the faucet itself will not produce secondary lead pollution to the water source, and will never damage to human health,.It also can create a healthy kitchen and bathroom living water environment.

Zinc alloy: low-grade material, Zinc alloys are less dense than copper alloys. It doesn’t feel as heavy as a copper faucet. The surface of the zinc alloy is easily oxidized from the inside wall. The white oxidized powder may appear on the surface.

The strength is much worse than copper,.The service life is not long. High lead included. A tap made of zinc alloy will rot if it is only one to two years old. Now zinc alloy is mainly used to make the handle of the faucet, which is die-cast with zinc alloy, and then chrome plated. Most of the faucet handles in the market are zinc alloy.

Attention: Based on the shortcomings of zinc alloy faucets, the faucet manufacturer has improved the internal structure. They changed the water part inside the faucet to the copper body, but the shell is still cast by zinc alloy, which is,” zinc-coated copper “(zinc alloy body with brass inner structure). It is cheap and durable, which has become a new trend in recent years.

ABS engineering plastics: PC+ABS( engineering plastics alloys).Its chemical Chinese name is plastic alloys,

This material has not only excellent heat resistance, dimensional stability, and impact resistance of PC resin, but also excellent processing fluidity of ABS resin. ABS faucet is the cheapest, environmentally friendly, non-toxic, non-pollution, exquisitely shaped, simply and conveniently installed. It also meets national drinking, civil drinking water standards. But it’s easy to age and smell.ABS based faucets are usually found in the lower end of the market.

2. According to the structure, faucets can be divided into single-type, double-type, and triple-type faucet. In addition, there are single handle and two-hand handle.

Single – the link can be connected to a cold water pipe or hot water pipe. The dual-type can connect hot and cold pipes at the same time, mostly for bathroom basin and kitchen dish basin with hot water supply. In addition to the hot and cold water pipes connected, triplet type can also be connected to the shower nozzle, mainly for bathtub faucet. A single handle faucet can adjust the temperature of hot and cold water through a handle, and the double handle needs to adjust the cold water pipe and the hot water pipe respectively to adjust the water temperature.

3. According to the opening mode, faucets can be divided into screw type, spanner type, lift open type, and induction type faucet. When the screw handle is opened, it rotates many times. The spanner handle generally only needs to be rotated 90 degrees.

Lift open handle only need to lift up for water; As long as faucet sensor the hand under the faucet, induction type faucet will automatically water. There’s also a faucet that turns off later. After turning off the switch, the water will run for a few seconds before it stops, when turning off the faucet, The dirt on your hands can be rinsed off again, which is generally used in public places.

4. According to the spool, faucets can be divided into rubber core (slow open spool), ceramic spool (quick open spool) and stainless steel spool, and so on. The most critical factor affecting faucet quality is a spool. The faucets with rubber spools are mostly screw type in iron, which have been basically eliminated; Ceramic spool faucets have emerged in recent years. It has good sealing performance, and it is quick opening and quick closing, and generally used; Stainless steel spool is more suitable for areas with poor water quality.

Detailed Faucet Manufacturing Process

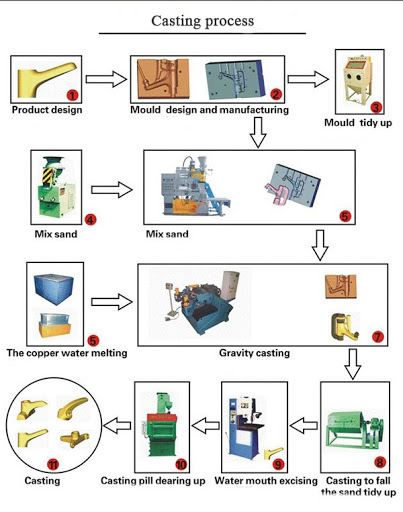

Here is the faucet production process flowchart

1. Casting

The casting process of faucets usually refers to the process of making products from molten alloy. The liquid alloy is injected into the prepared casting mold, then solidified, and we obtain the blank or part of the required shape weight.

Sand casting is a traditional casting process that the main modeling material uses sand. Because the sand casting is cheap and easy to obtain which used in molding materials, at the same time the molds are easy to manufacture, they can adapt to single-piece production, batch production, and mass production of castings. For a long time, sand casting is always the basic process in casting production. The internal structure of the valve body metal is loose that used sand casting, so it is easy to form “trachoma”, “stoma” and other internal defects. Although these defects may not be found in appearance, after a period of use, it will have some problems with water leakage and improper sealing.

Gravity casting is the method of the manufacture of castings using metallic materials and pouring molten metal into casting to obtain castings under gravity. As a metal mold can be cast hundreds to tens of thousands of times, so metal casting is also called permanent casting. The high-grade faucets usually adopt gravity casting. The inner structure of the body metal is compact, qualified, and its life is long. The weight difference between the gravity cast body and the sand cast body is about 1/4.

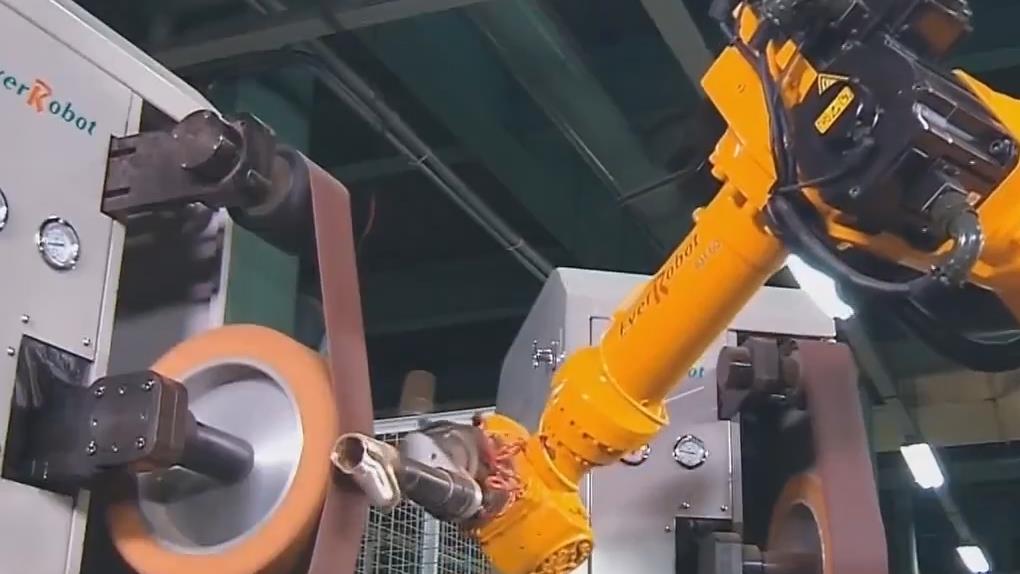

2. Machining and polishing of faucets

Machining: After the copper casting is annealed, Use CNC machine tools for turning, milling, drilling, creating, grinding, boring and so on for a variety of cutting, which makes the workpiece to reach the desired dimensional accuracy and shape position accuracy and meet the requirements of the design.

Polish the product after finishing machining, remove the burrs from the surface, rough surface and potholes, make the surface of the product without obvious trachoma, porosity defects. After polishing is finished, it should be polished. The surface of the workpiece can be ground with the high-speed rotation of the hemp (cloth) wheel make it smooth and bright.increase the brightness and finish of the product, and the lines are more smooth and smooth.

3. Faucet Finishes

The faucet finish is basically the final coat or surface of the faucet spout, handles, sprayer, and other components.

Now the main faucet finish technology on the market is electroplating, which uses electrolysis to deposit metal or alloy on the surface of the workpiece to form a uniform, dense, and good bonding metal layer. Electroplating is usually divided into chrome plating, nickel plating, titanium gold plating, etc. In addition, there are some other methods used infrequently such as baking varnish, porcelain, imitation gold electrophoretic paint. After the faucet is polished and formed, the relevant surface treatment should be carried out according to the design requirements, and then the faucet salt spray test is required to make sure that the salt spray test can reach the national target.

Faucet plating process: The first step is ultrasonic dewaxing and cathode electrolysis of oil. Electrolytic degreasing, activation, coarsening, post-recycling, neutralization, surface conditioning, presoaking, sensitization, acceleration, positive electrolysis, negative electrolysis, water washing, neutralization, acid copper, activation, cleaning, nickel plating, recycling, Cleaning, chrome plating, etc. Copper plating can make the electroplated layer get a finer structure, and the tiny defects and small pinholes on the surface of the faucet can be covered up to achieve satisfactory results. The effect of nickel plating improves the corrosion resistance of the faucet surface and can be highly polished. Chrome plating prevents corrosion and maintains brightness, improves surface hardness, and improves wear resistance.

The quality of the electroplating surface treatment is judged by a 24-hour acetic acid salt spray test (the test equipment is a salt spray tester) and a coating thickness gauge can be used to identify the thickness of various metal coatings. Generally speaking, the thickness of the coating is up to the standard, and the salt spray test can pass. The appearance of electroplating quality is fully inspected by quality inspection and recorded.

Here are some popular faucet finishes:

Polished Brass

The polished brass faucet is loved by all. It provides that vintage look that makes a bathroom look awesome.

Advantages: Easy to clean; durable; can be matched with other accessories and fittings without stress.

Disadvantages: It costs more than chrome and brushed nickel finishes.

Polished brass has been made to fit in with today’s style, so that it can be used in any setting, be it modern or traditional, and still look great.

Satin Brass

Satin brass is polished brass with a nicer twist. It has a brushed-gold look that makes it look classy. It’s not very conspicuous, but it looks bold.

Advantages: durable; It has a nice accent color without needing the polish; It hides fingerprints and water spots, thanks to the nice matte finish.

Disadvantages: More expensive than polished brass; It is hard to fit with other accessories and fittings.

Oil-Rubbed Bronze

Oil-rubbed bronze provides a beautiful alternative to brushed nickel and standard chrome and provides your bathroom with a better, more traditional look.

Advantages: durable; easy to clean; easy to match oil-rubbed bronze with accessories and other fixtures; Just like Satin Brass, it hides water spots and fingerprints.

Disadvantages: It is more expensive than other finishes, such as chrome and brushed nickel.

Oil-rubbed bronze works perfectly with traditional and Tuscan or Mediterranean settings

Copper

When you use copper faucets in your bathroom, you get a feeling of wealth, as copper is very conspicuous and bold. When you add some subtle but beautiful material like marble on the countertop, you get an even better feel.

A benefit of using copper is the antibacterial property of the material, as well as the fact that it is easy to find.

A major disadvantage of using copper is that a good copper finish would require more maintenance than other options like oil-rubbed and chrome bronze. Also, copper is not very durable and also very difficult to match with other accessories.

Copper faucets are best used in the farmhouse and Tuscan settings beautiful patina.

Satin Bronze

Satin bronze is known for its nice and smooth finish that steals a little from both copper and oil-rubbed bronze. The presence of a subtler color makes this finish more flexible to be able to fit in different bathroom styles and settings.

Advantages: durable; easy to clean and maintain; It is a great alternative to copper and a lighter option than oil-rubbed bronze. Water spots and fingerprints won’t show.

Disadvantages: more expensive; It is difficult to match with accessories and other fixtures.

Some of the styles it works with include: Traditional, eclectic, and Mediterranean.

Polished Nickel

With polished nickel, you can get the smooth and shiny finish you love. It is darker than chrome and changes its color in different lightings.

The advantage of polished nickel is the ease with which it can be cleaned and the fact that it is durable. It is the best alternative to brushed nickel faucets.

A major disadvantage that polished nickel has is that it is costly and difficult to match with other accessories and fixtures. Apart from that, it looks great on a wide range of settings.

Brushed Nickel

Nothing beats the soft metallic look of brushed nickel.

Advantages: durable; easy to clean; It tends to keep its finish longer than oil-rubbed bronze and chrome. It doesn’t show wear, fingerprints or water spots; It is easy to match with accessories and other fixtures; It is not as expensive as others. It is more expensive than chrome but not as much as oil-rubbed bronze.

Disadvantages: It does not work well with stainless steel. It tends to blend in instead of standing out.

Chrome

Chrome is the most popular finish used.

Advantages: inexpensive; durable; easy to clean and maintain; It matches easily with other fixtures and accessories.

Disadvantages: It shows fingerprints and water spots.

Matte Black

Thanks to their ability to match other items like vanities and accent pieces, black faucets are very popular in the bathroom. To make a classy statement in your bathroom or a small renovation that doesn’t require changing all aspects of your bathroom, you should consider a matte black finish.

Advantages: easy to clean; easy to coordinate with other bathroom accessories; It does not show dirt, fingerprints, or water spots.

Disadvantages: hard to match other fixtures to it; It is costly compared with more popular finishes, such as chrome and brushed nickel.

Solid Colors

These kinds of faucets are not very expensive, and they aren’t finished with metal. Instead, they use epoxy or enamel finishes that are easy to clean. The most popular options are ivory, black, and white.

Mixed Metallic Tones

This kind of finishing requires more than one metal or material for the finishing of the kitchen faucet. It needs to be properly matched to the décor, or you might end up with something odd in your kitchen. You can make delightful combinations with polished brass with satin nickel, polished chrome to brushed nickel, white and nickel.

4. Faucet Polishing

The major difference you find in the price between quality production faucets and others is polishing. When many faucet finishes come out of the finishing process, they aren’t all that perfect. However, polishing changes that outlook. In many mid-range faucets, you find that polishing is done by machine at the end of the process. To get the trademark lustrous finishes required for high-end faucets, you need to do careful and very skilled, time-consuming hand polishing. You have to do this several times during the finishing process.

To achieve this, the native brass is polished to a high sheen to remove all possible blemishes. Then the undercoating of the faucet takes place with zinc or nickel. This undercoat is given a careful hand polish. Then you apply the finish to one or more coats and hand polish the faucet.

It takes some time to master the art of hand polishing. Too much of it can cut through the finish, exposing the undercoat while too little will not give you the brilliance you desire. It is worth it at the end of the day when you have a finish with luster and depth that shows the world that the faucet is a premium product.

5. Faucet assembly

A set of faucets often consists of several parts. Assembly is in the final stage. The quality of the product (from the design of the product, the manufacture of the parts to the assembly of the product) is finally guaranteed and inspected by the assembly. Therefore, assembly is the key link to determine product quality. It is very important for ensuring and further improving product quality to make a reasonable assembly process and adopt an effective assembly method to ensure the assembly precision.

First, equip various assembly tools and parts, then start to connect, which include detachable connections such as spool, mesh tip, non-detachable connection such as joint and water inlet foot, etc. To install the spool (porcelain spool), fix the gland pin with a torque wrench or lock the porcelain spool with a socket torque wrench. When installing inlet foot or water level and hex nut, lock them with 10mm hex wrench (seal “O” ring at inlet foot and water level in advance). The bathtub faucet should be installed with the water separator switch.

The next step is to test the water. First, clamp the faucet on the test bench according to the working state. Open the left and right inlet valves respectively, open the spool, and flush the inner cavity of the faucet beforehand. Then close the spool to install the net tip pad and net tip, and use a wrench and other tools to gently tighten.No water seepage is necessary. Do not lock the parts too hard to avoid damage.

The next step is the pressure test. all sealing surfaces checked without leakage are qualified. Test qualified products to the assembly line installed pressure cap, handle, hot, and cold watermark. Finally, attach accessories, and a wipe packaging box. During the process of quality, there is an inspection process, Operator self-test, and Sampling inspection of the finished product.

6. Factory inspection of taps

After the finished product of the faucets is put into storage, the finished product inspector carries on the sampling inspection. The inspection items include casting surface, thread surface, appearance quality, assembly, marking, spool sealing test, faucet sealing performance test, etc. Strictly implement the sampling scheme and judging principle. Stick to the last step of the quality of taps.